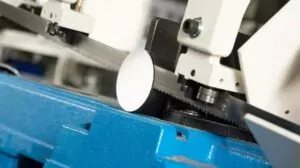

You demand accuracy and durability for your industrial drilling applications. Rong Fu’s drilling machines deliver with robust construction, tailored configurations, and features designed to maximize your productivity.

We offer an wide range of Drill Press Machines. We have grouped our Drill Press machines by Belt and Gear Type to help you quickly find the model that suits your needs.

Perfectly suited for metal drilling and available in configurations for any type of drill bit and drilling application, our drilling machines / drill presses can be supplied with a range of lubrication and speed setting options in bench-top or floor-standing configurations.

We manufacture belt type and gear driven drilling machines & drill presses with a wide range of options and features:

Our customers recognise the high quality and reliability of our drill presses. This comes from 40 years of experience in matching products to specific customer needs.

Two core principles have supported our success:

We are an OEM manufacturer of choice in North American and European markets because we control all stages of design, manufacturing and testing and do not outsource.

Our commitment to quality is demonstrated by our in-house management of the production cycle of development, manufacture and testing, with quality assurance carried out during all stages of the design and manufacturing process.

This enables us to swiftly respond to customer requests for specific features and products. In-house manufacturing ensures that we have expertise on hand to answer service and use queries rapidly and expertly, saving time for our customers.

We practice strict quality control and testing procedures and maintain ISO9001 registration for our processes through all stages of the manufacturing process. Our drill presses meet or exceed the requirements of global markets, including CE certification in Europe

All equipment is rigorously tested and calibrated by our expert staff before it is shipped and supplied with the test results and samples. This provides our customers with peace of mind that our drill presses will arrive ready for work.

We previously looked at choosing a metal cutting bandsaw blade, installing & adjusting blades, and breaking them in. Now let’s discuss the features of bimetal

In today’s metalworking and mechanical workshops, mill drill machines have an important role to play in maximizing productivity and minimizing waste. Rong Fu manufactures a

Metal cutting bandsaws are standard equipment for machine shops and metal manufacturing across a wide range of industries. The metal cutting bandsaw is such a

| Service | Cookies | Description |

|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

| Facebook Pixel | fr | Helps in determining efficiency of our advertising policy. |

| Youtube | APISID, CONSENT, HSID, LOGIN_INFO, PREF, SAPISID, SIDCC, SID, SSID, ST, VISITOR_INFO1_LIVE, YSC | Stores various information regarding user's preferences. |

| Service | Cookies | Description | |

|---|---|---|---|

|

|

Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

|

|

Facebook Pixel | fr | Helps in determining efficiency of our advertising policy. |

|

|

Youtube | APISID, CONSENT, HSID, LOGIN_INFO, PREF, SAPISID, SIDCC, SID, SSID, ST, VISITOR_INFO1_LIVE, YSC | Stores various information regarding user's preferences. |