A Better OEM Metal Cutting Bandsaw: The Rong Fu RF-712N Story

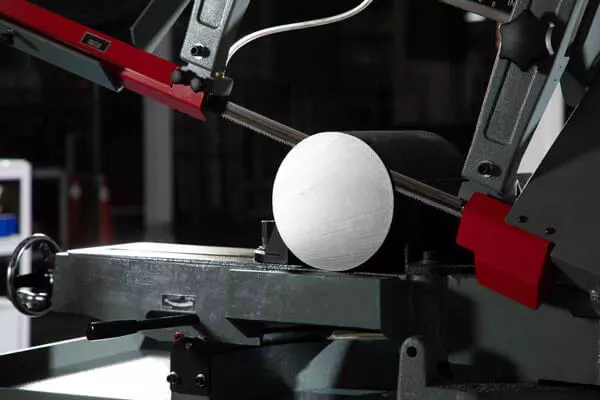

The Rong Fu RF-712N: a case study in metal cutting bandsaw evolution We’re going to take a look at the features that we have introduced

Rong Fu is a metal cutting band saw manufacturer. We are the OEM manufacturer for many global brands and offer configurations to suit each market and customer requirement.

We have a history of over 50 years of in-house production and our bandsaw machines can be found in small workshops and large machine shops worldwide.

Our extensive range includes high speed and variable blade speed manual and semi-automatic band saw machines with a wide selection of accessories and sizes. These can be provided with horizontal, vertical or variable blade alignment.

We have a strong customer base who recognise the high quality and reliability of our band saw manufacturing. This is because our approach to production and quality control has come from our long experience of matching products to the needs of all types of customer.

We achieve this by including all the requirements of band saw design, manufacturing and testing into our production processes.

Our commitment to quality is enabled by our management of the whole process of equipment development, manufacturing and testing. Unlike some band saw suppliers we do not outsource our production process.

We control quality at all stages of the design and band saw manufacturing process. This enables us to respond quickly to customer requests for specific features and products. In-house manufacturing ensures that we have expertise on hand to respond to service and use questions rapidly and expertly, saving time for our customers.

We practice strict quality control and testing procedures and maintain ISO9001 registration for our processes. Our metal cutting band saws meet or exceed the requirements of global market regulators, including CE certification in Europe.

All equipment is rigorously tested and calibrated by our expert staff before it is shipped, offering our customers peace of mind that our bandsaws will arrive ready for work.

Metal cutting band saw technology needs to be updated and improved to meet changes in customer requirements over time.

The introduction of new materials in manufacturing and demand for rapid cutting, portable machines and heavy duty cycles while maintaining strict safety controls are embedded in our research and development cycle.

Our primary concern is ensuring that customers can achieve the results they want from safe, affordable, and reliable equipment. To do this we listen to our customers and build their feedback into our improvement program.

The Rong Fu RF-712N: a case study in metal cutting bandsaw evolution We’re going to take a look at the features that we have introduced

Vertical integration is an effective method of maintaining control over supply chain, production and scheduling for OEM mill drill manufacturing. Rong Fu uses vertical integration

Manufacturers of mill drills and metal cutting bandsaws are offering digital control options for their OEM and ODM products. This industry trend is driven by

For over 50 years, Rong Fu has been a leading OEM manufacturer of high-quality metal cutting band saws and mill drill machines. We supply globally recognized brands with reliable, efficient metalworking machinery, made in Taiwan to Toyota Production System quality standards.

As a vertically integrated band saw manufacturer, we control all design, manufacturing, and quality processes in-house, enabling rapid customization of specifications including variable speeds, hydraulic downfeed, coolant systems, blade alignment configurations, and control panel designs. Our 50+ years of OEM experience allows us to quickly respond to specific feature requests and develop product variations tailored to your market requirements and brand specifications.

Our manufacturing processes are ISO 9001 certified, and all band saw products meet CE certification requirements for European markets. We also maintain UL and CSA listings for North American markets. Every unit undergoes rigorous testing and calibration by our expert staff before shipment, with test documentation and actual cut samples included to verify performance meets specified tolerances.

Unlike suppliers who outsource production, we maintain complete in-house manufacturing at our Taiwan facility, providing superior quality control, faster response times to technical questions, and the ability to implement design modifications quickly. Taiwan manufacturing offers established reliability for US and EU markets, stable supply chains free from geopolitical trade restrictions, and a proven track record of delivering high-quality metalworking equipment to global brands.

We’ve implemented flexible supply chain management specifically designed for OEM customers with varying order quantities and delivery schedules. Our in-house production capabilities allow us to accommodate both consolidated shipments for cost efficiency and staggered deliveries to match your inventory requirements. Lead times vary based on customization level and order volume—contact us with your specific requirements for accurate timelines.

Our extensive product line spans portable, bench-top, and floor-standing models with cutting capacities from 4″ to 20″. We offer horizontal, vertical, and variable blade alignment configurations, manual and semi-automatic operation, variable and high-speed blade options, gear-driven systems for high-torque applications, DC motor technology, hydraulic downfeed, integrated coolant systems, digital readouts, and touch screen control panels to match diverse industrial applications.

Every band saw ships with comprehensive calibration documentation, test cut samples measured to verify tolerance compliance, and complete technical specifications. Our quality control team performs in-line inspections throughout production and conducts final testing using touch probe verification for dimensional accuracy. This documentation provides traceability and assurance that equipment arrives ready for immediate production use.

We work collaboratively with OEM partners to identify market-specific features that enhance your brand value, from advanced DC motor technology and touch screen interfaces to application-optimized configurations. Our design and engineering team helps you incorporate differentiating features that address emerging customer preferences for safety, efficiency, and user experience, while our proven Taiwan manufacturing quality supports premium brand positioning.

Because we maintain in-house manufacturing and engineering expertise, we provide rapid, expert responses to service questions, application guidance, and troubleshooting support directly from the engineers who designed and built your equipment. This eliminates delays associated with outsourced production and ensures your customers receive accurate technical assistance when needed, supporting your brand reputation.

We’ve designed our production processes to accommodate various OEM partnership scales, from established brands requiring container-load quantities to emerging brands building market presence. Our flexible manufacturing approach allows us to discuss MOQs that align with your business growth stage and market entry strategy. Contact us to discuss your specific volume requirements and partnership structure.

Our ISO 9001 certified processes integrate quality control at every production stage, from incoming material inspection through final calibration testing. As a vertically integrated operation controlling all manufacturing steps, we maintain consistent standards without the variability introduced by outsourced components. Each band saw undergoes identical testing protocols, and we provide statistical process control data to OEM partners requiring documented quality assurance for their supply chain compliance.

| Service | Cookies | Description |

|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

| Facebook Pixel | fr | Helps in determining efficiency of our advertising policy. |

| Youtube | APISID, CONSENT, HSID, LOGIN_INFO, PREF, SAPISID, SIDCC, SID, SSID, ST, VISITOR_INFO1_LIVE, YSC | Stores various information regarding user's preferences. |

| Service | Cookies | Description | |

|---|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. | |

| Facebook Pixel | fr | Helps in determining efficiency of our advertising policy. | |

| Youtube | APISID, CONSENT, HSID, LOGIN_INFO, PREF, SAPISID, SIDCC, SID, SSID, ST, VISITOR_INFO1_LIVE, YSC | Stores various information regarding user's preferences. |